1. Introduzione

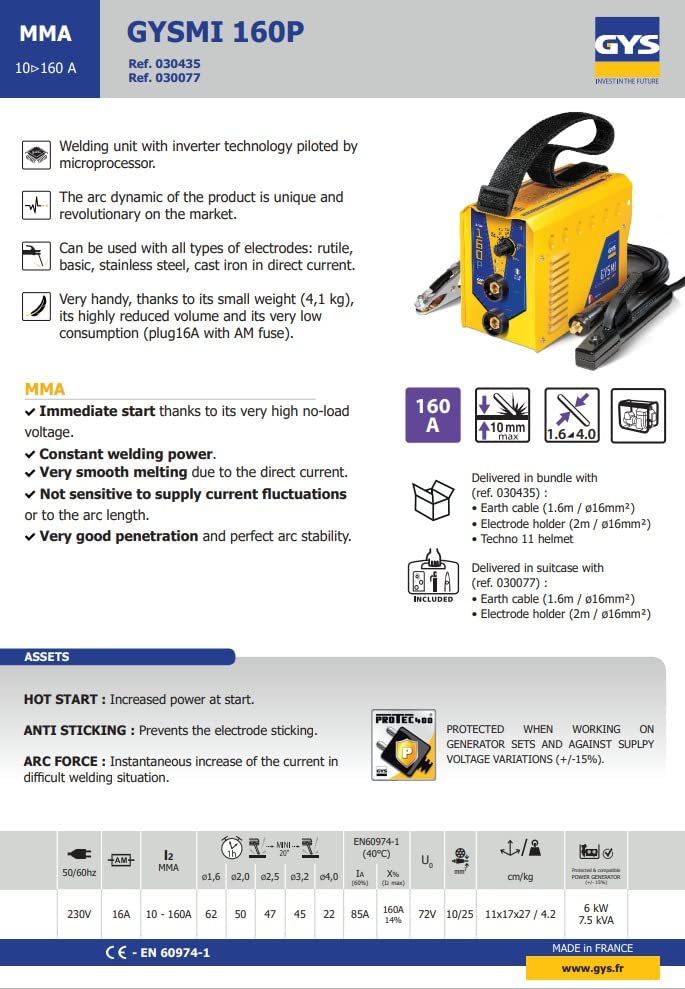

This manual provides essential information for the safe and effective operation, setup, and maintenance of your GYS Gysmi 160P Inverter MMA Welder. The Gysmi 160P is a 230V inverter-based electrode welding machine designed for repair and maintenance tasks. It is capable of welding with various common electrode types, including rutile, basic, stainless steel, and cast iron, operating in direct current (DC) mode. This unit incorporates PROTEC400 technology, offering protection against overvoltage up to 400V, undervoltage, e voltage fluttuazioni.

Key features include microprocessor-controlled inverter technology, unique arc dynamics, and a compact, lightweight design (4.1 kg) for portability and low power consumption (compatible with 16A plug with AM fuse).

2. Istruzioni di sicurezza

Quando si utilizzano attrezzature per la saldatura, dare sempre priorità alla sicurezza. La mancata osservanza di queste istruzioni può causare lesioni gravi o mortali.

- Elettro-shock: Welding current can cause fatal electric shock. Ensure proper grounding. Do not touch live electrical parts or electrodes with bare skin or wet gloves. Wear dry, insulating gloves and protective clothing.

- Fumi e Gas: Welding produces fumes and gases that can be hazardous to health. Work in a well-ventilated area. Use local exhaust ventilation or a respirator if necessary.

- Raggi dell'arco: Arc rays can burn eyes and skin. Wear a welding helmet with an appropriate shade filter. Protect other personnel in the area with non-flammable screens or curtains.

- Incendio ed esplosione: Welding sparks and hot slag can cause fires. Keep flammable materials away from the welding area. Have a fire extinguisher readily available. Do not weld on containers that have held flammable materials.

- Ustioni: Hot metal and slag can cause severe burns. Wear protective clothing, including long sleeves, pants, and safety shoes.

- Pacemaker: Persons with pacemakers should consult their doctor before welding. Electromagnetic fields from welding can interfere with pacemakers.

- Manutenzione: Scollegare l'alimentazione prima di eseguire qualsiasi manutenzione o assistenza. Le riparazioni devono essere eseguite solo da personale qualificato.

3. Prodotto finitoview e componenti

The GYS Gysmi 160P is a compact and robust inverter welder. Familiarize yourself with its main components before operation.

Figura 1: GYS Gysmi 160P Inverter MMA Welder, showing the control panel, output terminals, and carrying strap.

Figura 2: Close-up of the Gysmi 160P front panel, detailing the current adjustment knob, power switch, and electrode diameter indicators.

Componenti principali:

- Manopola di regolazione della corrente: Used to set the welding current (Amperes) based on electrode diameter.

- Power Switch (ON/STOP): Accende o spegne la saldatrice.

- Electrode Diameter Indicators: Markings around the current knob indicating recommended current ranges for different electrode diameters (e.g., Ø1.6mm, Ø2.0mm, Ø2.5mm, Ø3.2mm, Ø4.0mm).

- Positive (+) Output Terminal: For connecting the electrode holder cable.

- Negative (-) Output Terminal: For connecting the earth clamp cavo.

- Tracolla: Per un facile trasporto dell'unità.

- Griglie di ventilazione: Located on the sides for cooling the internal components. Ensure these are not obstructed.

Figura 3: The robust black carrying case provided with the Gysmi 160P, designed for protection and portability.

4. Impostazione

Una corretta impostazione è fondamentale per una saldatura sicura ed efficace.

- Posizionamento: Place the welder on a stable, level surface in a well-ventilated area, away from flammable materials. Ensure adequate space around the unit for airflow through the ventilation grilles.

- Collegamento elettrico: Connect the welder's power cord to a suitable 230V, 50/60Hz power outlet. The unit is designed for a 16A plug with an AM fuse. Ensure the power supply is protected against overvoltage e sottovolttage.

- Connessione via cavo:

- Collegare il cavo del portaelettrodo al terminale di uscita positivo (+).

- Collegare la terra clamp cavo al terminale di uscita negativo (-).

- Terra Clamp Allegato: Attacca la terra clamp securely to the workpiece or a metal workbench that is in direct electrical contact with the workpiece. Ensure a clean, bare metal contact point for optimal electrical conductivity.

- Inserimento dell'elettrodo: Insert the appropriate electrode into the electrode holder. Ensure the electrode is dry and free from damage.

Figura 4: The Gysmi 160P welder shown with its included accessories, such as the earth clamp and electrode holder, ready for connection.

5. Istruzioni per l'uso

Follow these steps for effective welding with your Gysmi 160P.

- Accensione: Turn the power switch to the 'ON' position. The power indicator light should illuminate.

- Select Electrode: Choose an electrode suitable for your material and desired weld. The Gysmi 160P supports rutile, basic, stainless steel, and cast iron electrodes.

- Imposta corrente: Adjust the current adjustment knob to the recommended amperage for your chosen electrode diameter and material thickness. Refer to the markings on the control panel (e.g., 40A for Ø1.6mm, 160A for Ø4.0mm).

- Tecnica di saldatura:

- Wear all necessary personal protective equipment (welding helmet, gloves, protective clothing).

- Strike the arc by lightly touching the electrode to the workpiece and quickly lifting it slightly to establish a stable arc.

- Maintain a consistent arc length and travel speed. The Gysmi 160P features 'Hot Start' for easier arc ignition, 'Anti Sticking' to prevent electrode sticking, and 'Arc Force' for improved arc stability in difficult welding situations.

- Weld in a continuous motion, ensuring proper penetration and bead formation.

- Spegni: After welding, turn the power switch to the 'STOP' position. Allow the unit to cool down before storage.

Figura 5: An operator demonstrating the use of a GYS Gysmi 160P welder, highlighting the importance of proper safety equipment during operation.

6. Manutenzione

Una manutenzione regolare garantisce la longevità e le prestazioni ottimali della vostra saldatrice.

- Pulizia: Periodically clean the exterior of the welder with a dry, soft cloth. Ensure ventilation grilles are free from dust and debris to prevent overheating. Do not use solvents or abrasive cleaners.

- Ispezione dei cavi: Ispezionare regolarmente i cavi di saldatura, il portaelettrodo e il contatto di terraamp per eventuali segni di danni, tagli o collegamenti allentati. Sostituire immediatamente i componenti danneggiati.

- Magazzinaggio: Store the welder in a dry, clean environment, protected from dust and moisture. Use the provided carrying case for transport and storage to prevent damage.

- Pulizia interna: For internal cleaning, it is recommended to have the unit serviced by qualified personnel to blow out dust from internal components using compressed air. This should only be done with the power disconnected.

7. Risoluzione Dei Problemi

Questa sezione affronta i problemi più comuni che potresti incontrare.

| Problema | Possibile causa | Soluzione |

|---|---|---|

| La saldatrice non si accende | Nessuna alimentazione; Cavo di alimentazione difettoso; Guasto interno | Controllare la presa di corrente e l'interruttore automatico. Verificare che il cavo di alimentazione non sia danneggiato. Se il problema persiste, contattare l'assistenza. |

| Nessun arco o arco debole | Poor earth connection; Incorrect current setting; Wet or damaged electrode; Loose cable connections | Garantire terra clamp has good contact. Adjust current. Use dry, new electrodes. Check all cable connections. |

| Gli elettrodi si attaccano frequentemente | Low current setting; Incorrect arc length; Electrode type mismatch | Increase current. Practice maintaining proper arc length. Ensure electrode is suitable for material. |

| Overheating / Thermal protection activated | Exceeding duty cycle; Obstructed ventilation; High ambient temperature | Allow welder to cool down. Clear ventilation grilles. Reduce welding time or current. |

8. Specifiche tecniche

Detailed specifications for the GYS Gysmi 160P Inverter MMA Welder.

Figura 6: Official product sheet for the GYS Gysmi 160P, detailing technical specifications and features.

| Caratteristica | Specificazione |

|---|---|

| Numero di modello | 030077 |

| Processo di saldatura | MMA (arco metallico manuale) |

| Ingresso volumetage | 230V, 50 / 60Hz |

| Intervallo attuale | 10 - 160 A |

| Diametro elettrodo | Ø 1.6 to 4.0 mm |

| Ciclo di lavoro (40°C) | 160A al 14% |

| Circuito aperto Voltage(U0) | 72 Volt |

| Power (60% / Max) | 6 kW / 7.5 kVA |

| Protection Technology | PROTEC400 (Overvoltage up to 400V, Undervoltage, voltage Fluctuations) |

| Dimensioni (L x P x A) | Dimensioni: 42.3 x 17.9 x 36.7 cm |

| Peso | 6.62 kg |

| Materiale | Metallo |

| Paese di origine | Francia |

9. Garanzia e supporto

For warranty information, technical support, or service inquiries, please refer to the documentation provided with your purchase or contact GYS customer service directly. Ensure you have your model number (030077) and purchase date available when contacting support.

GYS is committed to providing high-quality products and support. Do not attempt to repair the unit yourself, as this may void your warranty and pose safety risks.