1. Prodotto finitoview

The Watts 3/4 inch Lead Free Reduced Pressure Zone (RPZ) Assembly is engineered to safeguard potable water supplies from contamination due to backsiphonage or backpressure. This device complies with national plumbing codes and water authority requirements, making it suitable for continuous pressure piping applications and cross-connections identified as health hazards.

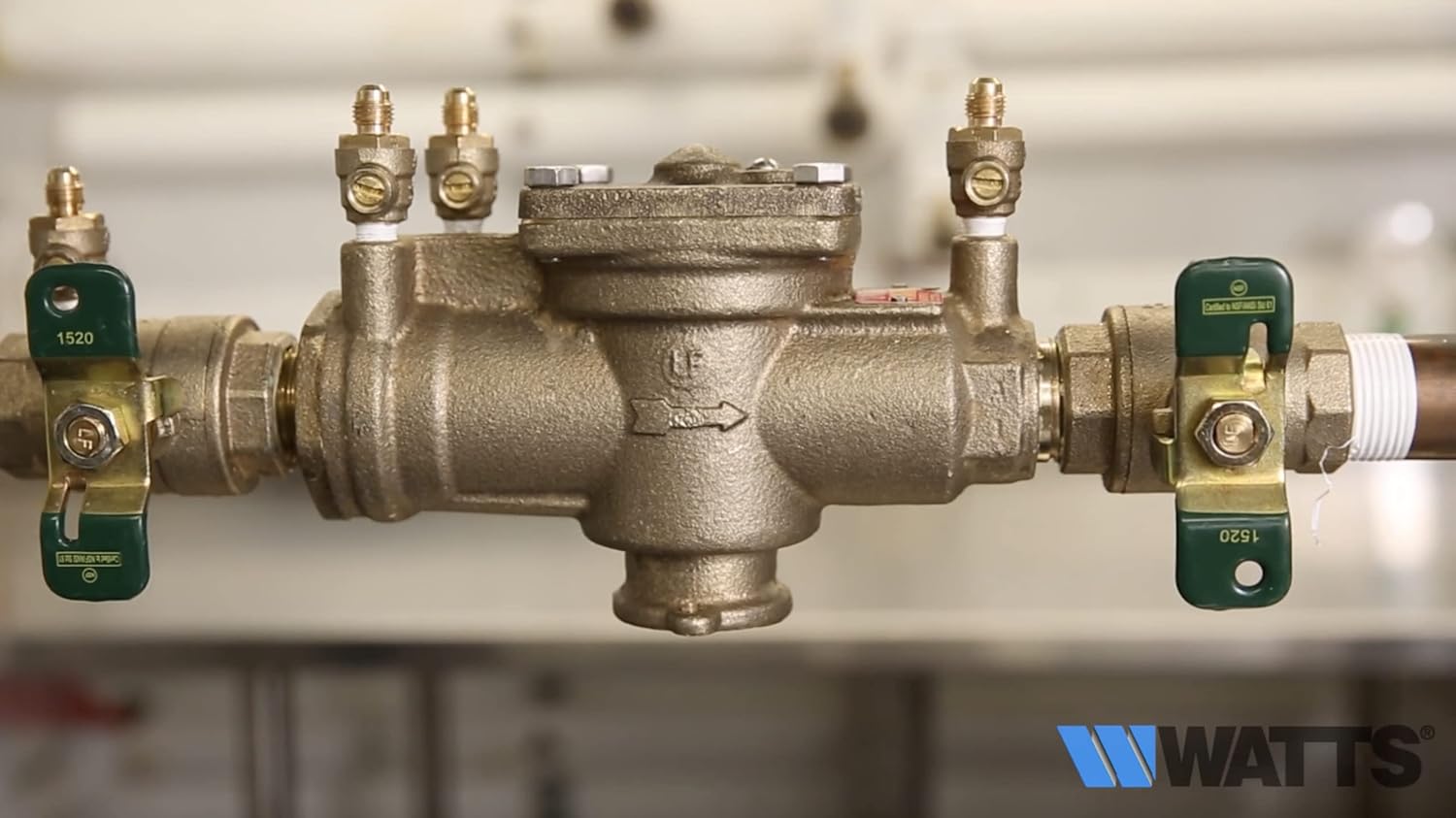

Image 1.1: The Watts 3/4 inch Reduced Pressure Zone Backflow Preventer assembly.

Image 1.2: Visual representation emphasizing the backflow preventer's role in protecting potable water supplies.

Caratteristiche principali:

- Costruzione durevole: Features a lead-free bronze body for longevity and compliance.

- NPT Connections: Equipped with National Pipe Tapered (NPT) inlet and outlet connections for secure installation.

- Integrated Shutoffs: Includes quarter-turn, full-port, resilient-seated ball valve shutoffs for easy control.

- Manutenzione semplificata: Designed with a single access cover and modular check construction to facilitate in-line repairs and maintenance.

- Low Pressure Drop: Large body passages ensure minimal pressure loss across the assembly.

- Caratteristiche di sicurezza: Captured springs enhance safety during maintenance procedures.

- Test galli: Top-mounted test cocks are included for convenient testing and verification of proper operation.

2. Informazioni sulla sicurezza

Always adhere to local plumbing codes and regulations during installation and maintenance. This device must be installed by a qualified professional. Failure to follow instructions may result in property damage or injury.

- Ensure the water supply is shut off and depressurized before beginning any work.

- Indossare adeguati dispositivi di protezione individuale (DPI), tra cui occhiali e guanti di sicurezza.

- Do not install backflow preventers in pits unless explicitly approved by local codes.

Image 2.1: Important note regarding installation of backflow preventers in pits. Always consult local codes.

3. Istruzioni per l'installazione

Proper installation is crucial for the effective operation of the backflow preventer. This device should be installed in a location that allows for easy access for testing and maintenance.

3.1 Controlli pre-installazione

- Verify that the assembly size (3/4 inch) matches the pipe size.

- Inspect the unit for any visible damage that may have occurred during shipping.

- Ensure all necessary tools and materials are available, including pipe sealant or thread tape.

3.2 Passaggi di installazione

- Preparare la tubazione: Ensure the piping is clean and free of debris. The assembly must be installed horizontally, with the relief valve pointing downwards.

- Orientare la valvola: Observe the flow arrow cast into the valve body to ensure correct orientation with the direction of water flow.

- Collegamento alla tubazione: Apply appropriate pipe sealant or thread tape to the NPT connections. Carefully thread the assembly onto the pipes, ensuring a tight, leak-free seal. Avoid overtightening.

- Support the Assembly: Provide adequate support for the assembly to prevent stress on the piping connections.

- Open Shutoff Valves: Slowly open the inlet and outlet shutoff valves to allow water to fill the assembly. Bleed any trapped air from the system.

- Controllare eventuali perdite: After installation and pressurization, thoroughly inspect all connections for leaks.

Immagine 3.1: Primo piano view of the valve body, highlighting the flow direction arrow for proper installation.

Image 3.2: A technician connecting the backflow preventer to the plumbing system.

Image 3.3: The Watts backflow preventer fully installed within a plumbing system, ready for operation.

4. Istruzioni per l'uso

The Watts Reduced Pressure Zone Assembly operates automatically to prevent backflow. No manual intervention is required during normal operation.

4.1 Funzionamento normale

- Under normal flow conditions, both check valves are open, and the relief valve remains closed.

- If a backpressure condition occurs, the first check valve closes, maintaining a pressure differential.

- If backsiphonage occurs, both check valves close, and the relief valve opens to discharge water, preventing contaminated water from entering the potable supply.

4.2 Shutoff Valves

The integrated quarter-turn ball valve shutoffs are for isolating the unit for maintenance or testing. Ensure they are fully open during normal operation to allow unrestricted flow.

5. Manutenzione

Regular maintenance and testing are essential to ensure the continued proper function of the backflow preventer. Local codes typically require annual testing by a certified backflow prevention device tester.

5.1 Routine Testing

- Annual testing by a certified professional is mandatory in most jurisdictions. The top-mounted test cocks are designed for this purpose.

- Keep records of all tests and maintenance performed.

5.2 Internal Component Access

The single access cover and modular check construction allow for easy inspection and replacement of internal components if necessary.

- Isolate the unit by closing both inlet and outlet shutoff valves.

- Depressurize the assembly by opening the test cocks.

- Remove the bolts securing the access cover.

- Carefully lift the cover to access the check valve assemblies and relief valve.

- Inspect components for wear, damage, or debris. Replace any worn or damaged parts with genuine Watts replacement parts.

- Reassemble in reverse order, ensuring proper seating of all components and tightening bolts evenly.

- Slowly repressurize the system and check for leaks.

Immagine 5.1: View of the internal components after removing the access cover, showing the check valve assemblies.

6. Risoluzione Dei Problemi

This section addresses common issues that may arise with the backflow preventer. For complex problems, contact a certified professional.

| Problema | Possibile causa | Soluzione |

|---|---|---|

| Water leaking from relief valve |

|

|

| Flusso d'acqua ridotto |

|

|

| External leaks from body or connections |

|

|

7. Specifiche

| Attributo | Valore |

|---|---|

| Numero di modello | LF009M3-QT |

| Misurare | 3/4 pollici |

| Materiale | Lead-Free Bronze |

| Dimensioni della connessione di ingresso | 0.75 pollici |

| Tipo di connessione di ingresso | Tubo conico nazionale (NPT) |

| Dimensioni della connessione di uscita | 3/4 pollici |

| Tipo di collegamento della presa | TNP |

| Pressione massima di esercizio | 175 PSI (libbra per pollice quadrato) |

| Numero di porte | 3 |

| Dimensioni (L x P x A) | Circa 4 x 4 x 6 pollici |

| Peso dell'articolo | 5.48 libbre |

| Codice UPC | 098268705553 |

8. Informazioni sulla garanzia

Watts products are manufactured to high standards and are typically covered by a limited warranty. For specific warranty terms and conditions applicable to your Watts LF009M3-QT Reduced Pressure Zone Assembly, please refer to the warranty documentation included with your product or visit the official Watts website. Warranty claims usually require proof of purchase and adherence to installation and maintenance guidelines.

9. Assistenza clienti

For technical assistance, replacement parts, or further information regarding your Watts 3/4" Reduced Pressure Zone Backflow Preventer, please contact Watts customer support.

- Watts Ufficiale Websito: www.watts.com

- Refer to the product packaging or the Watts websito per informazioni di contatto aggiornate (numeri di telefono, e-mail).