Introduzione

Questo manuale fornisce istruzioni essenziali per l'installazione, il funzionamento e la manutenzione sicuri ed efficaci della scheda di controllo del forno sostitutiva OEM Carrier HK61EA005. Si prega di leggere attentamente questo manuale prima di procedere con qualsiasi procedura di installazione o manutenzione. Conservare il manuale per riferimento futuro.

Informazioni sulla sicurezza

AVVERTIMENTO: L'installazione e la manutenzione di apparecchiature di riscaldamento, ventilazione e condizionamento dell'aria (HVAC) possono essere pericolose a causa della pressione del sistema, dei componenti elettrici e della posizione delle apparecchiature. Solo personale di assistenza qualificato e addestrato può installare, riparare o manutenere le apparecchiature HVAC. Il mancato rispetto di queste istruzioni può causare danni materiali, lesioni personali o morte.

- Scollegare sempre l'alimentazione dalla caldaia prima di installare o effettuare la manutenzione della scheda di controllo.

- Verificare che tutti i collegamenti elettrici siano sicuri e corretti, secondo le specifiche del produttore della caldaia.

- Indossare adeguati dispositivi di protezione individuale (DPI), tra cui occhiali e guanti di sicurezza.

- Assicurare la corretta messa a terra dell'impianto della caldaia.

Prodotto finitoview

Carrier HK61EA005 è una scheda di controllo per forni sostitutiva OEM, progettata per gestire le sequenze operative di un forno, tra cui accensione, controllo della ventola e monitoraggio della sicurezza. Questa scheda è compatibile con vari modelli di forni Carrier.

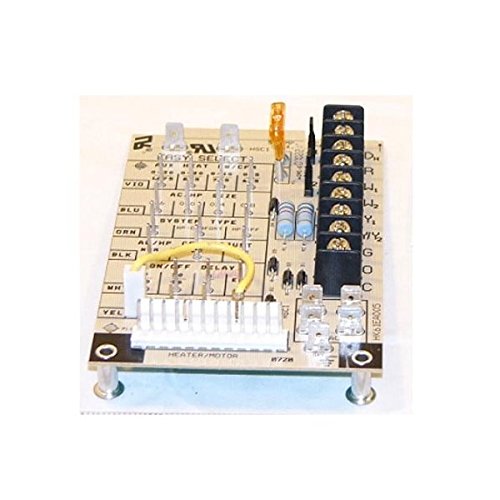

Figura 1: Scheda di controllo della caldaia Carrier HK61EA005. Questa immagine mostra la scheda a circuito stampato con vari terminali, ponticelli e componenti. Le caratteristiche principali includono le impostazioni dei ponticelli "EASY SELECT" per il tipo di sistema, le impostazioni di RITARDO ACCENSIONE/SPEGNIMENTO e le morsettiere per i collegamenti elettrici come D, R, W, W2, Y, Y2, G, O e C. È visibile un ponticello giallo che collega due pin sulla scheda.

Configurazione e installazione

- Disconnessione dell'alimentazione: Spegnere tutta l'alimentazione elettrica della caldaia dal pannello di servizio principale. Verificare che l'alimentazione sia interrotta utilizzando un voltmetro.tage metro.

- Accedi alla vecchia bacheca: Aprire il pannello di accesso alla fornace per individuare la scheda di controllo esistente.

- Cablaggio del documento: Prima di scollegare qualsiasi filo, scatta fotografie nitide o crea uno schema dettagliato di tutti i collegamenti elettrici alla vecchia scheda di controllo. Annota la posizione e il colore di ciascun filo.

- Scollegare i fili: Scollegare con attenzione tutti i fili e i connettori dalla vecchia scheda di controllo.

- Rimuovere la vecchia scheda: Smontare la vecchia scheda di controllo dal telaio della caldaia. Notare come era fissata (viti, clip, ecc.).

- Installa la nuova scheda: Montare la nuova scheda di controllo HK61EA005 nella stessa posizione e orientamento della vecchia scheda. Assicurarsi che sia fissata saldamente.

- Collegare il cablaggio: Fare riferimento alle fotografie o allo schema e ricollegare con cura tutti i cavi e i connettori ai terminali corrispondenti sulla nuova scheda di controllo. Verificare attentamente ogni collegamento per verificarne la precisione e la tenuta.

- Impostazioni ponticello: Configurare i jumper "EASY SELECT" e i jumper ON/OFF DELAY sulla nuova scheda in modo che corrispondano alle impostazioni della scheda originale o alle specifiche del produttore della caldaia. Queste impostazioni determinano in genere il tipo di sistema (ad esempio, AC, HP) e i tempi di ritardo della ventola. Fare riferimento allo schema elettrico della caldaia per i requisiti specifici.

- Chiudi pannello di accesso: Una volta verificati tutti i collegamenti, chiudere e fissare il pannello di accesso alla fornace.

- Ripristina alimentazione: Ripristinare l'alimentazione elettrica della caldaia tramite il quadro elettrico principale.

Istruzioni per l'uso

Dopo l'installazione e il ripristino dell'alimentazione, la scheda di controllo della caldaia riprenderà la normale sequenza di funzionamento. La scheda gestisce le seguenti funzioni:

- Sequenza di accensione: Controlla la valvola del gas e l'accenditore per un avvio sicuro della caldaia.

- Controllo della ventola: Gestisce il funzionamento del motore del ventilatore interno in base alle esigenze di riscaldamento o raffreddamento e alle impostazioni di ritardo.

- Monitoraggio della sicurezza: Monitora costantemente vari sensori di sicurezza (ad esempio, sensore di fiamma, interruttori di finecorsa) e spegne la fornace se viene rilevato un guasto.

- Interfaccia termostato: Comunica con il termostato per ricevere chiamate di riscaldamento e raffreddamento.

Per dettagli operativi specifici, fare riferimento al manuale di istruzioni principale della caldaia.

Manutenzione

La scheda di controllo HK61EA005 non richiede alcuna manutenzione ordinaria. Tuttavia, la manutenzione regolare dell'intero sistema di riscaldamento è fondamentale per la sua longevità e il suo corretto funzionamento. Questa include:

- Sostituzione del filtro dell'aria: Sostituire o pulire regolarmente il filtro dell'aria della caldaia (in genere ogni 1-3 mesi) per garantire un flusso d'aria adeguato.

- Ispezione professionale annuale: Fate ispezionare e revisionare la vostra caldaia ogni anno da un tecnico HVAC qualificato.

- Pulisci il sensore di fiamma: Un sensore di fiamma sporco può causare un funzionamento intermittente della caldaia. La pulizia deve essere effettuata da un tecnico qualificato.

Prima di effettuare qualsiasi intervento di manutenzione, scollegare sempre l'alimentazione elettrica dalla caldaia.

Risoluzione dei problemi

Se la caldaia non funziona correttamente dopo l'installazione della nuova scheda di controllo, prendere in considerazione i seguenti passaggi per la risoluzione dei problemi:

- Nessun potere:

- Controllare l'interruttore automatico della caldaia.

- Assicurarsi che l'interruttore di disconnessione della caldaia sia in posizione "ON".

- Verificare tutti i bassi volumitage e ad alto volumetagI collegamenti alla scheda di controllo sono sicuri.

- La fornace non si accende:

- Verificare che il termostato sia impostato su "HEAT" e che la temperatura sia superiore alla temperatura ambiente della stanza.

- Controllare i codici di errore sulla scheda di controllo (se applicabile, fare riferimento al manuale della caldaia per l'interpretazione dei codici).

- Assicurarsi che la valvola di alimentazione del gas sia aperta.

- Verificare che il sensore di fiamma sia pulito e posizionato correttamente.

- La ventola non funziona correttamente:

- Controllare le impostazioni del jumper "ON/OFF DELAY" sulla scheda di controllo.

- Assicurarsi che l'impostazione della ventola del termostato sia corretta (AUTO/ON).

- Verificare i collegamenti del motore della ventola alla scheda di controllo.

- Codici di errore: Molte schede di controllo sono dotate di LED diagnostici che lampeggiano per indicare guasti specifici. Consulta il manuale originale della tua caldaia per un elenco dei codici di errore e il loro significato.

Se le procedure di risoluzione dei problemi non risolvono il problema, contattare un tecnico HVAC qualificato per ricevere assistenza.

Specifiche

| Numero di modello | Numero di modello: HK61EA005 |

| Numero di modello alternativo | CECOMINOD058414 |

| Marca | Supporto (sostituzione OEM) |

| Dimensioni del prodotto | 6 x 6 x 6 pollici |

| Peso | 0.01 once |

| Data prima disponibilità | 8 ottobre 2013 |

Garanzia e supporto

Per informazioni sulla garanzia relativa a questo ricambio OEM, fare riferimento ai termini forniti dal punto vendita originale o alla documentazione di garanzia specifica inclusa con il prodotto. Per assistenza tecnica, si consiglia di consultare un tecnico HVAC qualificato o le risorse di supporto del produttore originale della caldaia.